Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies KINJO RUBBER CO., LTD.

KINJO RUBBER CO., LTD.

Top share by construction method of earth-friendly ground improvement work

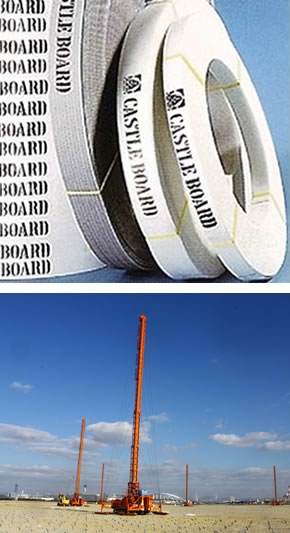

Castle board Drain Method

KINJO RUBBER CO., LTD.

"Castle Board drain method" increases in the strength of the ground by promoting the consolidation settlement of the soft ground

KINJO RUBBER CO., LTD. has a national high profile in recognition as a manufacturer of industrial rubber parts. They make the rubber-related businesses with a portfolio of a large number of unique and top market shares, even they are also focused on civil engineering-related businesses as two-second pillar. Construction materials developed by them of improvement work of soft ground using the "Castle board" boasts a large number of achievements throughout the country.

The "Castle Board drain method" is a type of ground improvement technique called "plastic drain method." Its method of and discharging the ground water by applying pressure to the ground to be implanted made of resin material, and facilitate the consolidation settlement to increase the strength of the ground. It is environmentally friendly since it is possible to significantly reduce the harvesting of natural resources. In addition, the environmental impact of its own technology has been utilized throughout the construction of the "Castle board drain method" used to driving development and material of material using the raw material impact on the environment is less "Cast machine" design and the like in consideration has been subjected. Therefore it accounts for about 70% and the high share of the work by the "plastic board drain method" in the country. Their technology has been adopted by large construction and also it can be said that the national projects such as Haneda Airport and Kansai International Airport and Kobe Airport, second Keihan Kadoma Junction and North Port and South Port and many other places.

They have a 70% market share by the orders consistently to construction of material development

They have established a business infrastructure by It was founded in rubber products business. After that, they expanded the business to the civil engineering-related business in 1965's. The opportunity was told from Osaka of general contractor, "Do you want to challenge in the production of ground improvement of material?". Then they worked on the production of "Castle board" as a material manufacturer, began a civil engineer-related businesses.

Employees say that the "This project will quit because unprofitable" since they were repeated failure. However, they were challenged to it with the feeling that the new Manufacturing. They work hard to quality improvement in unity. Whereby its business was gradually succeeded. They considered "We also need to know the field in order to do a good thing manufacturing" to 1975's. And they began to work on even construction.

They have their own construction the most current. They do consistently to design and construction-course observation of the development of material. Their customers of the leading general contractors have so much faith for them.

"We manufacture one unique product in one year" to be "HODO-KUN" which was created with the idea that, and their future direction”

They have the motto "We manufacture one unique product in one year". They focus attention on Braille blocks.

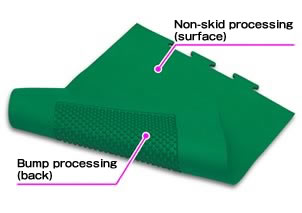

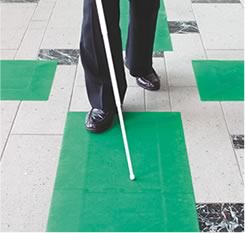

They have developed a "HODO-KUN" by improving the "walking difficulty, stumbling ease" of conventional inductive block (Braille blocks). "HODO-KUN" is visually impaired persons, elderly walking and stroller, wheelchair traveling such, everyone's taxiway that walk with confidence. They are offering a product that is stuck to the safety and security with the aim of barrier-free in the true sense.

Features of "HODO-KUN" is a soft feel transmitted from the difference and the foot of the sound and feel of when you hit in the white cane instead of irregularities tells us that a taxiway. It is grippy on wet and difficult stumbling in the water by reducing the step between the other on the floor. It also construction period is short and low price because it can be easily constructed. And it also becomes an evacuation road when you use a material that emits light among the darkness in the event of a disaster.

"HODO-KUN" is already Yao City Hospital, a large number of public institutions and hospitals, social welfare facilities, universities, financial institutions, have been adopted in the event venue. They are aiming to expand into the adoption and the world market in each venue of future it of Tokyo Olympic and Paralympic.

- KINJO RUBBER CO., LTD.

- ○Address: 1-4-25, Atobe Kitanocho, Yao City, Osaka, 581-0068, Japan

- ○TEL: +81-(0)72-992-2321

- ○FAX: +81-(0)72-993-7706

- ○Homepage: http://www.kinjogomu.jp/