Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies LASERCK CO., LTD.

LASERCK CO., LTD.

The fully automated "delinking operation" after punching

Master Blanker

LASERCK CO., LTD.

70% top share in Japan

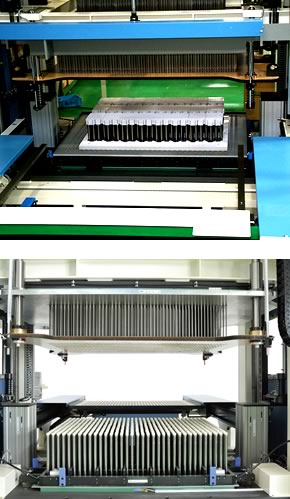

Master blanker is a fast blanking system that automates the delinking operation craftsmen had done manually far in paper containers and package of production process. About delinking operation, In the manufacturing process of the print box of "cut → Print → surface treatment → punching → separation (delinking operation) → folding → finish", it's work that separates the parts of the box of the product and the piece part. "Delinking operation" was heavy lifting craftsmen are separated by hand or hit it with a hammer. They provide automated conveyance during the process in conjunction with the optional products by mechanized it. Whereby they were high quality, high productivity and low cost of paper containers and packages the product.

In existing products job change (it is working to replace the contents of the package to separate) takes a hand part on take 1 hour. Their master blanker has its own method that can be changed automatically up and down the pin. Thus, their users can job change in just three minutes. The users to them to request the speed, they were overwhelmingly made the leap the production efficiency in response to it. Therefore, they have a share in Japan to 70%.

Untold story of the development

Mr. Chuji Yanagimoto of the current chairman, he has started with the engineers who have invited from outside the development of master blanker more than 10 years ago. The craftsmen had done delinking operation in heavy lifting, such as hammer hit and manually in a folding carton factory. Therefore, pile palette had been narrow in the factory. Furthermore, the work of removing the piece, leaving only the desired area as a product, it was considered common knowledge in the industry is that it is difficult to mechanize. They were challenged product development to solve by focusing on the two problems.

Mr. Yanagimoto punching craftsman was repeated trial and error in friendly competition with engineers in the places that are not known to other employees away from the past factory. They were allowed to complete the master blanker of the upper and the lower pin method after also created a few unit prototypes. They piled the study, they were unique sequence about 4,000 pins so that the pins hit in small part to its upper part. Furthermore, they are arranged approximately 1,400 pins to reduce the dent is protected tip thereunder with special resin material. Thereby now be evenly pressed by the master blanker correspond to different box shapes and sizes. Master blanker can blank in a complex shape precision was difficult in the machine until now.

They have manufactured most of the components of the master blanker in their factory, and they have obtained several patents. They think that "Without the general-purpose products make in-house." Whereby they now have in-house for more than 90% of the non-painting and welding. They are immediately able to respond to the needs of minor changes from the customer by the height of their in-house production rate. In addition, they can respond quickly to customers of any chance of failure. Therefore they can have a responsibility for their products.

Shape of paper containers and packages are diverse and complex. Meanwhile, the user requests a correspondence in multiple varieties and small lot. Their master blanker soon can support even change the shape of the product. And it is possible to fully automate the process. Their master blanker is the limelight, sometimes customers who have purchased in the past to purchase multiple additional later years.

High technology based on their many years of effort was found in industry. They are selected by the Ministry of Economy, Trade and Industry to the "first-time energetic manufacturing SME 300 companies" (2006), also won Excellence Award in the "Making 4th thing Japan Grand Prix" (2012). In addition to the August 2005, the Emperor and Empress visited their headquarters factory. In addition they have developed a new blanker with improved processing capacity in 2014.

They are based on the know-how that has been accumulated so far aim to further strengthen the technology development capabilities. And they are aiming to develop products that can accommodate delicate and friendly to the die-cutting of thin paper. They foreign markets not only Japanese market also with a view, their technology will continue to evolve.

- LASERCK CO., LTD.

- ○Address: 2-91, Wakabayashicho, Yao City, Osaka, 581-0038, Japan

- ○TEL: +81-(0)72-920-0394

- ○FAX: +81-(0)72-920-0392

- ○Homepage: http://www.laserck.com/