Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies SAKURA SEIKI CO., LTD

SAKURA SEIKI CO., LTD

Their products are world-class in function and design in technical strength, and No.1 of the market share in Japan.

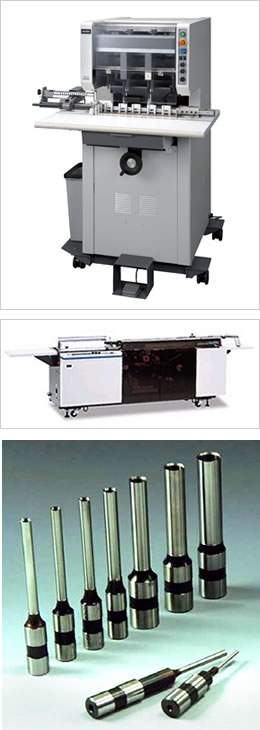

Large mechanical punch for professional use

SAKURA SEIKI CO., LTD.

It's Japan top share in the large mechanical punch industry

Grandfather of the current president began operation by Sakura Seiki in Osaka city for the purpose of manufacturing of science laboratory equipment in 1948. Relocated the head office and factory in Yao City in 1961, was advanced to the office equipment field in 1970. Then advance in the binding equipment field in 1981, was undertaken in the manufacture of mechanical punch for professional use. The motto of this company is "If we become if profit by selling at one for one year, it can be a business" and "We will get top in the niche field". Its company became No.1 with 70% Japan top share in the large mechanical punch industry.

Among the manufacturing of mechanical punch in our company, electrical control with a focus on software had been outsourced. But then, it brought up the engineer in-house, was allowed to establish a system that can produce in-house everything from five years ago.

The high-end models of automatic piercing machine "iR / iK series" is, and 2,200 rev / min high-speed rotation, high-precision drill in pursuit of sharp sharpness, allows precise perforation to paper at the bottom in the microcomputer control of newly developed. Also, when choosing a registration pattern head position-side gauge is an automatic movement, it is possible to greatly reduce the setup time. In addition, Japan's Marble pasting Machine Company’s share in the field, is it is greater than 50 percent, the "No.1"

“We can be anything produced”

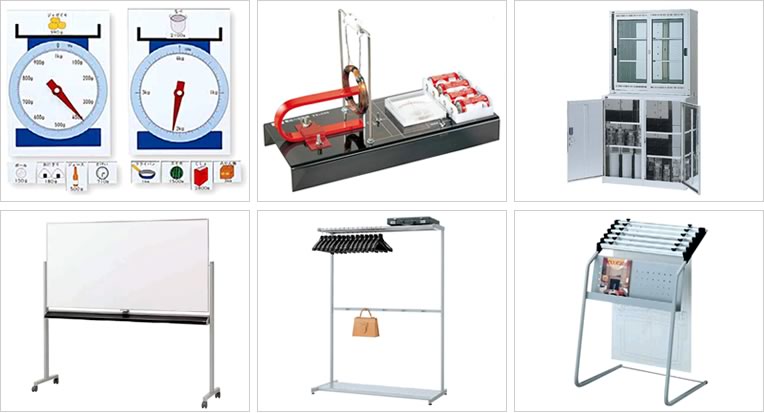

Sakura Seiki's strengths are development and design from the planning of the product (electrical and software and machinery all) leading to manufacturing, painting, and assembly, and then do all manufacturing in-house. The company can be responsible for up to finished product just hear only the images and concepts from the user, and to add features such as a user who is not even noticed. Therefore, further confidence and reputation as "whoever is willing to think that far" from the user, they are led to repeat orders. Since its inception, produce science laboratory equipment to be used in schools, further and office furniture (office equipment) and bookbinding machinery (stamp material, equipment), and due to the fact that I went all the way to production from the planning of different genres products, in-house is a gift of accumulated planning skills to.

Sakura Seiki's manufacture is a stainless steel medicine cabinet from materials of the magnet, white board, and the stamp material machine, there is a product that has been processed to make full use of various equipment. You'll see it if you look at the photo below. Number of products while the number of employees is 70 people in the current is also 1,200 goods. They all have in all are required equipment manufactured by the company in-house.

Ippei Muramoto president said "I will be well from people around asked to be 'What do you manufacture in Sakura Seiki?'. We have created a product in a variety of genres, it is not beyond description in various kinds of so few words also processing. So, last I say 'We can make anything.' . "

That as a result of "We can make anything" technology and organization, in 2009 I have been awarded the "Osaka Manufacturing Excellence Company Award".

"Changed the work of printing shop" passion for new products and science teaching materials

In the current Sakura has developed a new product of three using its own of soft and electrical-related technology in piercing machine development. Above all, after binding and processing equipment "Cutter & Creaser Aero Cut Quatro" is reputation as "changed the work of printing shop." So, put muscle of leaflet from the cut of the card, such as perforation, in processing capable, multi-function machines to finish, it is marvel for other companies.

For science laboratory equipment that we are made from the time of its inception, I have a strong commitment that "in education there is an indication of away from science, to provide educational materials to support the creation of now the support personnel of Japan". Also Sakura from now, the "unbreakable", "safety", "exact" science experiment equipment, and continue to make in the quality that cannot be imitated in inexpensive goods overseas, will create the possibility of Japan's future.

- SAKURA SEIKI CO., LTD.

- ○Address: 2-61, Kusunecho, Yao City, Osaka, 581-0814, Japan

- ○TEL: +81-(0)72-996-5528

- ○FAX: +81-(0)72-922-0592

- ○Homepage: http://www.sakura-seiki.co.jp