Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies Abel Co., Ltd.

Abel Co., Ltd.

World-first electrolytic stainless steel surface treatment technology -Super Black-

Abel Co., Ltd.

Ultra-thin film technology on stainless steel: “Super Black”

Stainless steel is said to be rust-resistant, durable, and beautiful, but the reason behind this is because when chromium is added to steel, chromium binds together with oxygen, creating a thin protective surface film (passivation film) and preventing corrosion.

By controlling this ultra-thin surface film, Abel succeeded in coloring stainless steel, which is considered to be difficult, and established a system called the “electrolytic coloring method.” After that, by specializing in the color black, Abel developed “Super Black,” an attractive and functional finish. It is now used in various fields.

Development process -Our unique electrolytic coloring method-

What triggered Abel Co., Ltd. to develop the electrolytic coloring method was that with aluminum window sashes becoming more colorful, customers started demanding that the stainless steel peripheral hardware be colorful as well. However, the conventional chemical coloring method was unable to yield consistent results, as this method requires human involvement, which can lead to color variation. To solve this problem, we decided to develop our own technology and succeeded in developing a unique technology, electrolytic coloring on stainless steel.

Electrolytic coloring is different from painting, so the color does not come off, while keeping the same gloss and weather resistance of chemical coloring. This method has vastly improved the appearance and consistency of the products to which it is applied, leading to widespread market acclaim.

Expanding possibilities by specializing in black

After developing the electrolytic coloring method, Abel decided to specialize in the color black for its products. Black is a color that is not swayed by trend, and in electrolytic coloring, black is more stable compared to other colors, able to create a refined look, and prevents reflection of light.

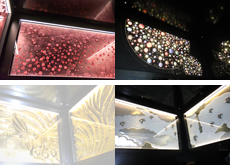

In this way, Super Black’s appearance and durability is valued in various fields, such as in the interiors of major retailers, where a classy appearance is important; it is also used for exteriors of home appliances and precision equipment, much of which requires dimensional accuracy. Super Black is also used in the interior of elevators in the Tokyo Skytree, which opened in May 2012. We expect the technology to be seen in diverse places in the future as well.

Future direction

We are now working on the manufacturing of black stainless steel coil stock using continuous electrolytic coloring treatment. Instead of using electrolytic coloring treatment on the pre-molded parts provided by customers, providing stainless steel coil stock with Super Black processing enables us to provide stainless steel materials with added value, allowing us to grow our sales into multiple markets both inside and outside of Japan.

Abel will strive to collaborate with customers by giving them excellent value and by working to develop new technology and new products that fit the needs required by the times.

- Abel Co., Ltd.

- ○Address: 1-1-42, Minamitaishido, Yao Ciry, Osaka 581-0056, Japan

- ○TEL: +81-(0)72-992-5401

- ○FAX: +81-(0)72-993-9912

- ○E-mail: info@abel-s.co.jp

- ○Homepage: http://www.abel-s.co.jp