Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies Nakata Co., Ltd.

Nakata Co., Ltd.

Specular finish achieved without abrasive polishing

Specular finish cutting technology

Nakata Co., Ltd.

Specular finish without polishing

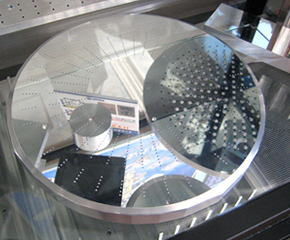

In the semiconductor industry, reflecting substrate (aluminum) is used for equipment for heat treating silicon wafers. The most important thing in order to manufacture reflecting substrate is specular finish.

Specular finish makes the surface of aluminum material parts look like that of a mirror. Normally, parts are shaped by cutting, then the surface is polished to perfect it; however, Nakata Co., Ltd.’s specular cutting process technology achieved specular finish (surface roughness of Ra0.02-0.04) with cutting only (no polishing whatsoever).

Development process -Working toward the advancement of specular finishing techniques-

Prior to Nakata’s development of specular finish cutting, achieving a specular finish on aluminum through abrasive polishing was common practice. However, the companies which use these products pointed out a major drawback of polishing; a small amount of abrasive residue gets left behind on the mirror-like surface, leading to tarnishing on the polished surfaces.

To address this, Nakata began developing a method to make a specular finish possible without the use of abrasive polishing. With our industry-leading technical capabilities, a beautiful, no-tarnish specular finish can be achieved with just cutting. It was with this in mind that development began.

Through trial and error, many attempts were made using a multitude of cutting tools and lubricants. Nakata combined the knowledge and experience of every company employee, eventually leveraging this storehouse of technical know-how in order to make specular finish cutting technology possible.

Specular finish cutting made possible through top-notch technical capabilities

Regular cutting methods cannot achieve a specular finish. Through a wealth of research and development, Nakata has been able to achieve specular finish cutting technology.

The number one advantage of specular finish cutting technology is that polishing of the material is not required. Because of this, delivery can be made in a short time, the specular surface is exposed to fewer contaminants and impurities, and the procedure is less expensive than performing polishing. In addition to this, the surface comes out clear rather than cloudy white due to any pitting that the abrasive media may cause, thus preventing microscopic imperfections on the surface.

Specular finish cutting technology can produce seamless items up to 300mm in width. Nakata is the only company in the world capable of this feat.

This technology was selected for the “MONODZUKURI New Selection in KANSAI” showcase for 2013. The Kansai Bureau of Economy, Trade and Industry established this promotion in 2012.

Future direction

After the success of developing specular finish cutting technology, we continue to work on improving our technical capabilities, including significant dedication to research and development. As a result, specular finish cutting technology is now also available for curved surfaces.

Going forward, Nakata will continue to advance this technology with an eye toward processing curved surfaces, as well as generally improving the quality of our products.

- Nakata Co., Ltd.

- ○Address: 5-1-15, Kamiocho, Yao Ciry, Osaka 581-0851, Japan

- ○TEL: +81-(0)72-996-8621

- ○FAX: +81-(0)72-922-8291

- ○E-mail: info@nakata-ss.co.jp

- ○Homepage: http://www.nakata-ss.co.jp