Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies ISEL CO., LTD.

ISEL CO., LTD.

Mixer with Stacked Elements

ISEL CO., LTD.

The word “mixer” typically reminds people of a device for cooking. However, mixers are used in various industries for all sorts of purposes, such as mixing compounds when formulating drugs for the medical field, mixing solvents in chemical engineering, mixing ingredients in the food processing field, and mixing cultures and samples in the biotechnology industry.

The Mixer with Stacked Elements developed by ISEL is a mixing device which employs a new and unprecedented mixing method which can be utilized for the mixing of fluids and gas streams.

Characteristics of the MSE

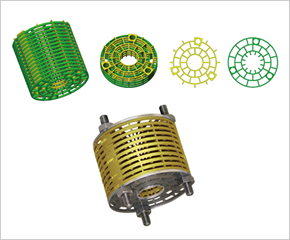

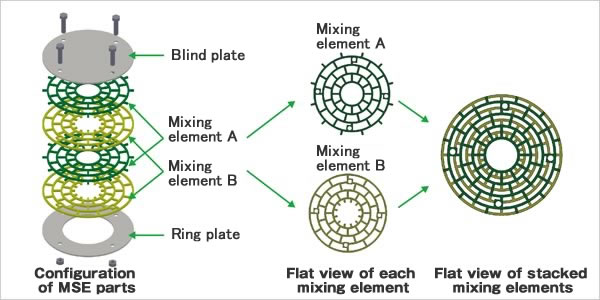

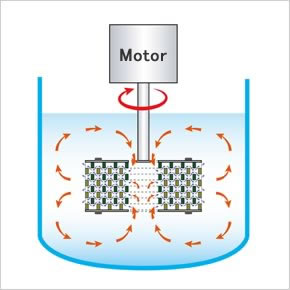

The MSE works in such a manner that two types of spider-web-like disks called “mixing elements” are stacked together.

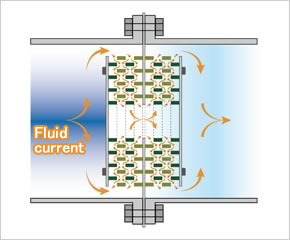

Stacking multiple “mixing elements” together makes small holes, through which fluids and gas streams pass, creating turbulence and vortex action. Because of its structure, the MSE has a wide range of uses, and it can be used for both static mixing and dynamic mixing.

Static mixing -As a static mixer-

Static mixers do not rotate impellers using motors, but the impellers are placed within a pipe, then fluids and gas streams flow in the pipe, mixing them as they pass through the pipe. The MSE can be used as a static mixer. To accomplish this, the mixing elements are stacked together with ring plates at both ends sandwiching them. Compared to conventional static mixers, the MSE can be produced easily and allows mixing in a short distance.

Dynamic mixing -Functioning as a vaneless impeller-

Impellers with vanes are used in most stirring tanks, but the MSE can be used as a vaneless impeller. The MSE as an impeller has larger surface areas compared to disk turbine impellers, which are normally used; therefore, energy conveyed from the motor to the material being mixed disperses, allowing gentle mixing. This is expected to be used in the biotechnology industry for mixing cell samples that are weak against shear stress that typically occurs during stirring. The fluids and gas streams are mixed and stirred repeatedly within the MSE, allowing the mixing time to be reduced greatly.

Mixing elements can be manufactured not just with metal, but also with various materials like plastic, Teflon, ceramics, etc. Furthermore, outer and inner diameters and size of the though-holes can be changed, enabling the production of equipment tailored to the task.

Entering a new market

ISEL CO., LTD. is a manufacturer that produces many types of equipment, but did not start out as a company which developed products for the chemical industry. The development of the MSE proved to be a challenge to the company’s resources. Nonetheless, ISEL persevered toward the goal of entering a new market.

Despite having limited resources, ISEL progressed through development by utilizing the country and prefecture’s aid programs, collaboration with research facilities like colleges, and outside resources. It took approximately 3 years to finish the development.

As its mechanism and shape are different than conventional mixers, the MSE is expected to be used in many fields. Data analysis is being done for applications outside of the medical and biotech fields.

Future direction

The name of the company came from the meaning “selling ideas.” ISEL has been developing numerous new products and technologies, following the philosophy of always innovating and creating something new. Many of ISEL’s products are best-sellers in Japan. The MSE is expected to be a product that will open new doors for ISEL.

- ISEL CO., LTD.

- ○Address: 1-2-16, Atobe Kitanocho, Yao Ciry, Osaka 581-0068, Japan

- ○TEL: +81-(0)72-991-0450

- ○FAX: +81-(0)72-994-7593

- ○Homepage: http://isel.jp