Home Top Market Share in Yao/Unique Companies

Top Market Share in Yao/Unique Companies FUJI ELECTRONICS INDUSTRY CO., LTD.

FUJI ELECTRONICS INDUSTRY CO., LTD.

To achieve the overall optimization of the production line by using a heat treatment process

High-frequency quenching

FUJI ELECTRONICS INDUSTRY CO., LTD.

Induction hardening is supported by behind the automotive and machine tools

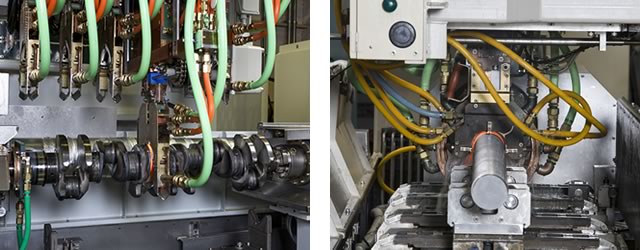

Engine parts of an automobile that we are used normally, it is common to carry out heat treatment in order to enhance the durability and hardness (the metal etc. is heated and cooled to vary the hardness and nature). Shape such as crankshaft complex parts among the engine parts is carried out only in the quenching is required place. Induction hardening is one of the quenching methods corresponding to the demand. F FUJI ELECTRONICS INDUSTRY CO., LTD. is engaged in the development and manufacture of machinery and equipment of the induction hardening.

Induction hardening is how the heat treatment is performed by using the phenomenon of "induction heating" magnetic force by applying an electric current to the coil to heat the object passes through the object.

Its benefits;

1) It can respond to partial quenching

2) It can control the depth of hardened

3) It is the energy saving because it is heated only the surface portion

4) It does not emit harmful substances such as Co2

And more.

FUJI ELECTRONICS INDUSTRY CO., LTD. founded in 1960. They are depending on their customer's production environment, and propose a quenching method obtained from their rich development experience (total about 800 patents, utility model, including a pending).

One-shot hardening using the semi-open coil

Induction hardening is divided into move quenching method to move the position of the coil and the One-shot hardening method of the heat treatment in place. FUJI ELECTRONICS INDUSTRY CO., LTD. has a rich know-how of the one-shot hardening using the semi-open coil. "Move quenching method" is not possible to suppress the "baked uneven" and "baked escape". But if at once heating the whole in there own semi-open coil,

1) The energy saving by significant reduction in cycle time

2) They can be uniformly quenching in if it is complicated shapes

There are above advantages. Competitors that are doing the hardenability with open coil exist. But car manufacturers and machine tool manufacturers are evaluating their rich proposal made full use of the know-how and stable processing technology. Their market share in the production line of the crankshaft and a ball screw that high accuracy is required is to ensure a high of 80 percent level.

They propose a production line leading to total optimization

FUJI ELECTRONICS INDUSTRY CO., LTD. is also designing and proposal of the entire production line according to the needs of the customers in addition to it. For example, they may proposals for the customer at the line design leading to total optimization that is the standpoint reduce the polishing step of the post-process by devising a heat treatment process. It is one of the factors that have gained the top share in the parts they high accuracy, such as the crankshaft is required.

Their future prospects: Responding to globalization

Japanese automobile manufacturers and machine tool manufacturers are becoming relocated their production bases to other than Japan. Foreign automobile manufacturers are becoming more and more inquiries to them. Therefore, competition for orders of competitors, such as they and Europe and the United States have become increasingly severe. Under such environment, Fuji Electronic Industrial Co., Ltd. has adopted a human resources who are familiar with the situation of each country. They have the know-how that has delivered more than 260 units of the machinery and equipment to 16 countries so far. They have done the proposed activities of the machinery and equipment that takes into account the situation of local taking advantage of the experience. For example, since the quality of the cooling water is different in each country, they are doing the induction hardening of the development of mechanical equipment in consideration of the difference in water by repeated experiments. They delivery record for outside Japan of these activities were recognized, and they were also selected in the "global niche top companies 100 election" of the Ministry of Economy, Trade and Industry in 2014.

Aim of Fuji electronics industry is the inheritance of their knowledge that has been accumulated in the manufacturing performance that exceeds the inheritance '50. Their knowledge will be taught to the younger generation. They also take advantage of the wealth of know-how of the one-shot hardening by semi-open coil the future, and they propose activities to achieve the overall optimization of the production line. Thereby they support the automotive and machine tool manufacturers.

- FUJI ELECTRONICS INDUSTRY CO., LTD.

- ○Address: 6-71, Oihara, Yao City, Osaka, 581-0092, Japan

- ○TEL: +81-(0)72-991-1361

- ○FAX: +81-(0)72-991-1309

- ○Homepage: http://www.fujidenshi.co.jp/japanese/