Home Business PR Page

Business PR Page

Metal Products Manufacturing

TERADA Co., Ltd.

Welding process for thin-walled pipes, vacuum flanges, and fittings. The tip of the pipe has a wall thickness of t1.

Aluminum A1070, outside diameter 200φ, inside diameter 197φ Processed with partial wall thickness of t0.5. Depiction of product cut from an ingot.

SUJ2 scotch yoke shaft. It was cut from a 60mm outside diameter round bar. The process steps: turning -> machining -> quenching and polishing -> machining. The last machining process is after quenchin

2nd cylinder.SUS304L is processed. Inside diameter 18mm, overall length 133.2mm, precision of inside diameter is 10 microns. Lathe cut part product, unpolished per customer request. For this customer'

- Many of our products are used in universities and research facilities.

Because of this, we're confident not only in their precision, but also their aesthetics.

We specialize in a wide variety of products, even in small quantities.

We tend to have materials in stock, so we are often able to respond to rush orders. Please contact us for more information.

- We have extensive experience and manufacturing know-how on thin pipes.

SUS304, 220φ, t0.7, L400, with some tolerance for both inside and outside diameters.

Cylinders used in cryogenic refrigerators are 18φ inside diameter, L130, tolerance ±0.005. The degree of roughness is ▽▽▽ or better due to precision machine turning.

We also have experience with cutting hard materials such as stainless steel, aluminum, copper, brass, titanium, monel metal.

The lathe can adjust up to 540φ. The length can adjust up to 1500mm.

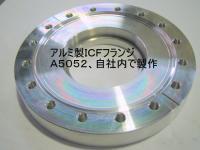

We can manufacture custom-ordered ICF flanges.

We can manufacture custom-ordered clamp flanges.

- Iwatani Industrial Gases Corp., ATEC Co. Ltd., Cryovac Corporation, and other cryogenic refrigerator manufacturers.

Our end users are universities and research facilities.

- We have been running a small factory in Higashiosaka for over 70 years. We moved to Yao in August, 2013 in order to expand our businesses. We intend to lead the way in Japanese manufacturing as a family company, while keeping an eye toward the future. We don't just believe in meeting our customer's expectations for quality and precision; we believe in EXCEEDING their expectations. To do this, we are always vigorously working on improving our technologies.

As a family company based in Yao, Japan, we will continue striving to lead the way into the future.

- Grant recipient from the Prototype Development Support Fund for Small and Medium Enterprises in 2012

-

Materials Processing Technologies Processing Products and Uses Stainless steel, aluminum, copper, brass "Turning of thin pipes

Example: cutting a pipe of 200φ and t0.7 with high precision in both inside and outside diameters."・Machined, Ground or Polished Ultrahigh vacuum apparatus, cryogenic refrigerators, high-pressure gas equipment Titanium, monel metal, hard-to-cut materials Experience working with hard-to-cut materials ・Machined, Ground or Polished Ultrahigh vacuum apparatus Aluminum Manufacturing of aluminum ICE flanges ・Machined, Ground or Polished Ultrahigh vacuum apparatus Stainless steel "Turning of thin flanges

Example: processing flanges of 400φ and t10 and dovetail groove cutting."・Machined, Ground or Polished Ultrahigh vacuum apparatus, cryogenic refrigerators, high-pressure gas equipment Stainless steel Processed surfaces can withstand ultrahigh vacuum apparatus.

Welding and leak tests can be conducted.・Machined, Ground or Polished

・WeldedUltrahigh vacuum apparatus, cryogenic refrigerators

-

Commodity Component Industry Cryogenic refrigerators (cryostats) for research facilities A variety of parts used for cryogenic refrigerators ・Medical Goods and Cosmetics

・Other ProductsUltrahigh vacuum apparatus for thin films, etc. Flanges ・Other Products Valves, etc. for high-pressure gas Valves ・Other Products

- Production capacity: Parts for cryogenic refrigerators: 30 sets a month

Production of various research materials and parts (single items): More than 50 per month

-

Machine Name Processing Capabilities Number of Machines NC lathe 540φ x 1500mm 1 Unit Machining center X axis: 1050mm, Y axis: 500mm 1 Unit Multi-purpose lathe 450φ x 850mm 2 Units NC milling machine X axis: 800mm, Y axis: 400mm 1 Unit Electrical discharge machine 0.2φ-5φ 1 Unit Drill press 2 Units Sawing machine Can cut up to 300φ 1 Unit Hoist 1.5t 1 Unit

- We mainly deal with research-related small lot manufacturing, so our facility is often able to respond to rush requests and projects with tight deadlines. Please contact us for more information.

We deal with cryogenic refrigerator manufacturers and ultrahigh vacuum apparatus manufacturers directly, so we are very confident in the precision and quality of our products.

We offer multiple services ranging from procurement of materials, processing, and welding, to leak detection and surface finishing.

Our well-trained, highly capable staff is ready and waiting to accept orders and consultations via email.

We typically have materials in stock, so most orders need only a schematic.

For more detailed information about our products or offers to act as alocal distributor,please fill out the following form.

Required item

Yao City Charm Creation Department

1-1-1 Honmachi, Yao City, Osaka Prefecture 581-0003 Japan

Click Here to Submit an Inquiry