Home Business PR Page

Business PR Page

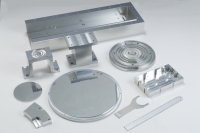

Precision and Medical Instrument Manufacturing

NAKATA Co., Ltd.

Our company strives to improve its technologies and skills, and works to create technological linkages with customers' enterprises to ensure processing quality. We are working to create an enterprise structure that can receive an ever greater amount of trust from its customers, and for that purpose acquired ISO 9001 certification in November 2000. Also, in the area of CSR we acquired ISO 14001 certification in November 2006. We hope that all of our customers will continue to offer us their support and patronage.

- Our primary manufacturing focus is on precision aluminum parts for semiconductor manufacturing equipment, liquid crystal manufacturing equipment, medical and pharmaceutical equipment, industrial robots, and aerospace machinery. We enthusiastically accept orders for various types of small batch and/or prototype and development products, as well as rush orders. In the area of microscopic process development, we have developed a method for processing φ5 micrometer diameter holes, and can process requests requiring mirror-surface machine processing technologies.

- We can handle a wide range of processing area sizes from a maximum of 650 mm X 1700 mm to a minimum of only a few micrometers. Guaranteed quality and precision varies by product, but as an example in the area of semiconductors we are capable of flatness within 0.02 mm onφ300 mm-use wafer trays, and within 0.01mm of processing measurement tolerance. Furthermore, we have a manufacturing structure in place that allows for the manufacture of single prototypes and/or products in development to mass produced processing of up to 5000 units per lot. In the area of microscopic processing technologies, we possess a level of technological expertise that is at the top of the class in this industry. We are capable of boring holes in complex shapes as narrow as 0.005 millimeters (5 micrometers) in diameter, and are able to process deep groves of 30 micrometers (aspect ratio: 100 times).

- Panasonic, Honda, Kyocera, Etc.

- ""Contribute to society through manufacturing, and strive towards the well-being of all of our employees.""

Our company motto is ""For the family,"" and we are always working to create better relationships with our employees, customers, suppliers, and cooperating companies. Our feelings towards these groups exceed that of business, and are rather the way one views family. It is our desire to further our friendships and relationships of trust with all.

- National Vocational Ability Examination Machine Processing Milling Machine Operation Level One Certification (Health, Labour and Welfare Ministry) 3 Persons

Advanced Proficiency Technician Certification (Health, Labour and Welfare Ministry) 2 Persons

Second Manufacturing Japan Grand Prize: Award of Excellence (Ministry of Economy, Trade and Industry) 4 Persons

Yao Manufacturing Master (Yao Chamber of Commerce) 3 Persons

Naniwa Expert Craftsman (Osaka Prefecture) 3 Persons

National IT Management Top 100: Grand Prize for Excellence (No. 1, No. 2) (Ministry of Economy, Trade and Industry)

Management Reform Authorized Enterprise (Ministry of Economy, Trade and Industry)

Manufacturing Medium- and Small-Scale Enterprise Product Development Assistance Project Authorization (Ministry of Economy, Trade and Industry)

Others

-

Materials Processing Technologies Processing Products and Uses Aluminum Alloys We can handle everything from thin-wall processing to deep bore processing. ・Machined, Ground or Polished Semiconductor Manufacturing Machinery Parts

Liquid Crystal Manufacturing Machinery Parts

Industrial Robot PartsAluminum Alloys Various Types of Alumite Processing, Etc. ・Surface Processing 1 (Plating) Semiconductor Manufacturing Machinery Parts

Liquid Crystal Manufacturing Machinery Parts

Industrial Robot PartsAluminum Alloys Full Plating, Etc. ・Surface Processing 1 (Plating) Semiconductor Manufacturing Machinery Parts

Liquid Crystal Manufacturing Machinery Parts

Industrial Robot Parts

-

Commodity Component Industry Automobiles Engine Fuel Spray Nozzles ・Automobiles Machine Tools Transportation Equipment Parts ・Precision Machinery Measuring Equipment Tray Parts, Fixture Parts ・Measuring Instruments Electronics Automobile Parts ・Electronic Instruments and Devices Home Appliances Development-Use Scroll Compressor Parts ・Home Appliances Communication Equipment Radiator Fins ・Communication Equipment Medical Instruments Partitioner Parts ・Medical Instruments

- We face a manufacturing structure that allows for rush orders (1-3 days after order) of prototypes and products in development, as well as lots of 5000 units.

-

Machine Name Processing Capabilities Number of Machines Vertical Machining Center HS430L(Sodick) Linear Motor-Car Drive, Extremely High-Speed Rotation Microscopic Processing Specialized Machinery 1 Units Vertical Machining Center 66VA(Okuma) Extremely High-Speed Large Scale Processing-Use Heat Variation Control Equipment Installed 2 Units Vertical Machining Center 56VA(Okuma) Extremely High-Speed Processing-Use Heat Variation Control Equipment Installed 2 Units Vertical Machining Center 46VA(Okuma) Extremely High-Speed Processing and Microscopic Processing-Use Heat Variation Control Equipment Installed 1 Units Vertical Machining Center TC-22B-0(Brother) We are capable of highly general purpose, highly maneuverable high-speed processing. 2 Units Vertical Machining Center TC-S2B(Brother) We are capable of handling special specifications through our manufacturing structure with high mobility. 1 Units NC Lathe LB300M(Okuma) Complex Processing Specialized Machine: Heat Variation Control Equipment Installed 1 Units Vertical Ram-Type Milling Machine (Excel Kasuga) General-Purpose Machining-Use (Width: 200 X Length 300) 7 Units Horizontal Drill Press (Koto) Horizontal Boring-Use Drill Press 2 Units CADCAM(Custom) 2.5 Dimensional-Use: 1 Unit + 3 Dimensional-Use: 1 Unit 2 Units CADCAM(Master carm) 2.5 Dimensional-Use: 1 Unit + 3 Dimensional-Use: 2 Units 3 Units Horizontal Drill Press and Tapping Board General-Purpose Boring and Tap Processing 12 Units Aluminum Cutter Excellent Cost/Performance Material Cutter 1 Units Hairline Polishing Machine We are capable of finishing surfaces to customers' specifications. 1 Units Digital Microscope (Keyence) We have microscopic processing testing equipment capable of a maximum of 5,000x. 1 Units 3D Measuring Equipment (Mitsutoyo) We measure to a level of precision of 5/10,000. 1 Units Surface Roughness Measuring Equipment(Mitsutoyo) We are capable of performing test data creation work. 1 Units Surface Temperature Measuring Equipment(Mitsutoyo) Guaranteeing precision comes first from the temperature of the work. 1 Units Constant Temperature (20 Degrees Celsius 0.5 Degrees Celsius) Testing Room We have equipment that maintains testing precision. 1 Units Other Supplementary Equipment We have a multi-product small-batch manufacturing management system developed in house. Microscopic 5 Axle Machining Center (Made by Roku-Roku) We possess an extremely high-precision microscopic processing MEGA, specified for simultaneous 5-axle processing.

There are only a few of these machines in Japan.1 Units

- ・ISO 9001 Acquisition:2000

・ISO 14001 Acquisition:2006

| ■ Address | 5-1-15, Kamio-Cho, Yao City, Osaka 581-0851, Japan |

|---|---|

| ■ TEL | +81-(0)72-996-8621 |

| ■ FAX | +81-(0)72-922-8291 |

| ■ Representatives | Hiroshi Tanaka |

| ■ Date of Establishment | 1977 |

| ■ Capital | 10,000,000 yen |

| ■ Number of Employees | 24 people |

| ■ Industry | Precision and Medical Instrument Manufacturing |

| ■ URL | http://www.nakata-ss.co.jp |

For more detailed information about our products or offers to act as alocal distributor,please fill out the following form.

Required item

Yao City Charm Creation Department

1-1-1 Honmachi, Yao City, Osaka Prefecture 581-0003 Japan

Click Here to Submit an Inquiry